Vacuum enthalpy cooling

VEK

- Baked goods crispness and stability throughout the day

- Germ-free: Extend shelf life by up to 3 weeks

- Enormous energy-saving potential

- Time savings of approx. 70 %

The VEK vacuum process takes the cooling of oven-hot products to a new dimension

The new “vacuum process” cools down baked goods faster than any previously known method. Baked goods hot from the oven are cooled down in just a few minutes. The cooled products are immediately available for further processing such as cutting or packaging. Cooling the baked goods by means of VEK vacuum cooling creates sustained crispness and stability in baked goods throughout the day. VEK vacuum cells from WP have been designed for the continuous pick-up of product carriers.

Long lasting crispness and stability throughout the day:

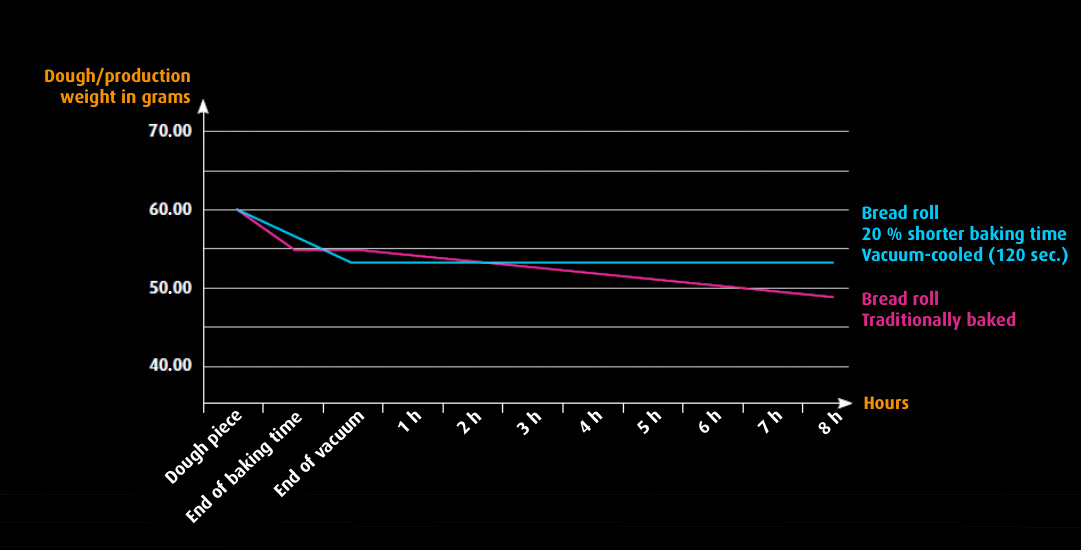

Weight loss or moisture loss using the example of bread rolls

WP DIFFERENTIAL PRESSURE MEASUREMENT (patented)

We measure the internal pressure of the products and the pressure in the cell. The advantage of this is that the difference in pressure can be adjusted for each specific product. The measurement takes place via an insertion probe in the middle of the product and a pressure sensor in the chamber. The result is saved in the recipe programme and stored for repeat runs.

Performance, maximum benefit, and modular options

WP VEK is the key to economic efficiency: cooling baked goods faster, saving energy. The products have a longer lasting crispness, remain firm longer, and are immediately ready to cut. The shelf life in the refrigerator is extended by up to three weeks.

- Extension of shelf life:

- Vacuum process kills germs and products are packaged germ-free. This extends the shelf life by up to 3 weeks.

- Fast cooling to cutting and packaging temperature:

- Cooling down to low temperatures in a very short time

- Minimum loss of moisture

- Time gain in the production process

- Energy cost savings

- Efficiency and time savings:

- Storage and transport temperatures at 4 to 8 degrees celsius

- Reduced energy input during full baking

- Fresh products for the customers faster

- Aromatic browning process only in 2nd baking phase

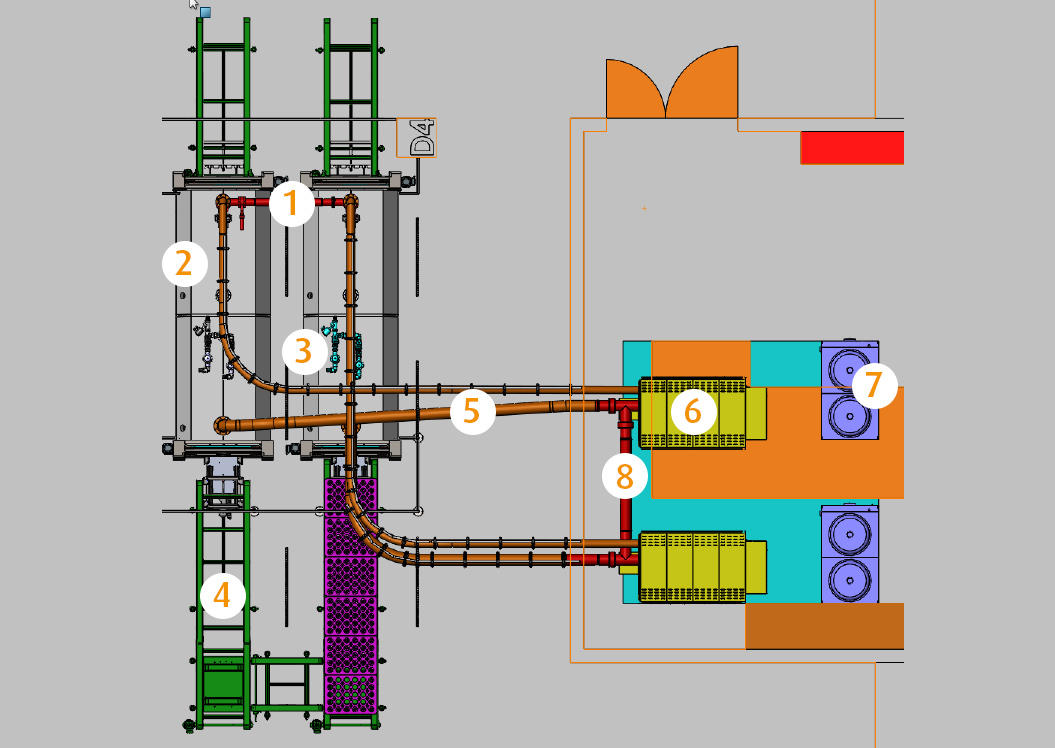

VEK 4000 AB 800

Consisting of 2,000 mm long modules

6 800 x 600 baking trays, different products can be transported on or in the tray

Maximum headroom: 475 mm

VEK 6000 AB 800

Consisting of 3000 mm long modules

10 800 x 600 baking trays, different products can be transported on or in the tray

Maximum headroom: 475 mm

For juicy, crisp baked goods of consistent volume

Toast

Ciabatta breads

Artisan rolls

Pretzel sticks

Slit rolls

Kaiser rolls

Panettone