Continuous multi deck oven

MEGADOR

- simple and variable

- modularly adaptable

- flexible in operation

When highest flexibility

needs minimum space

The MEGADOR Multi Layer Oven opens new dimensions for economic production of a wide range of bakery products. Additionally providing high baking quality and optimal usage of space. You can be sure that your requirements for top quality products, rapid amortisation, increasing competence in competitiveness and customer satisfaction will not only be achieved, but will surpass your expectations.

Product variation and economy

Flexible, space saving solutions are prerequisites for producing a large variety of products under economical circumstances. This is where the MEGADOR Multi Layer Oven presents itself as the ideal solution. The modular construction system offers flexibility, efficiency and tailor-made production for continuous or batch products. Even by frequent product changes and smaller batches, the automatic loading system ensures economic production processing.

Layer for layer – high quality products

Quality is can be measured even in continual processes, this is why care in the choice of raw materials, recipes and dough preparation methods are so important. Therefore the decision that must be made is for a perfect and reliable baking process, which guarantees unmistakable, continuous high quality reproduction of the goods. The MEGADOR Multi Layer Oven combines highest quality production and continual precision, creating a new milestone in baking technologies.

Investments for the future

With the MEGADOR Multi Layer Oven you invest in a baking system which is designed for the future. Whether you want to increase your range, or your baking capacities, the MEGADOR Multi Layer Oven is capable of meeting any challenge. The modular construction system enables the MEGADOR Multi Layer Oven to adapt or be extended to your new requirements. Standardised interfaces and cable connections guarantee a fast, unproblematic extension – so that you can practically build up your lead against competitors without any loss of time or costly delays in production.

Loaves and rolls simultaneously

In case of deckwise production the oven compartments in each oven can be used to bake different products. Temperatures and baking times can be programmed accordingly. In continuous processing, the oven can be divided into zones, so as to guarantee a perfectly optimised baking cycle for the required product. Different combinations are also possible.

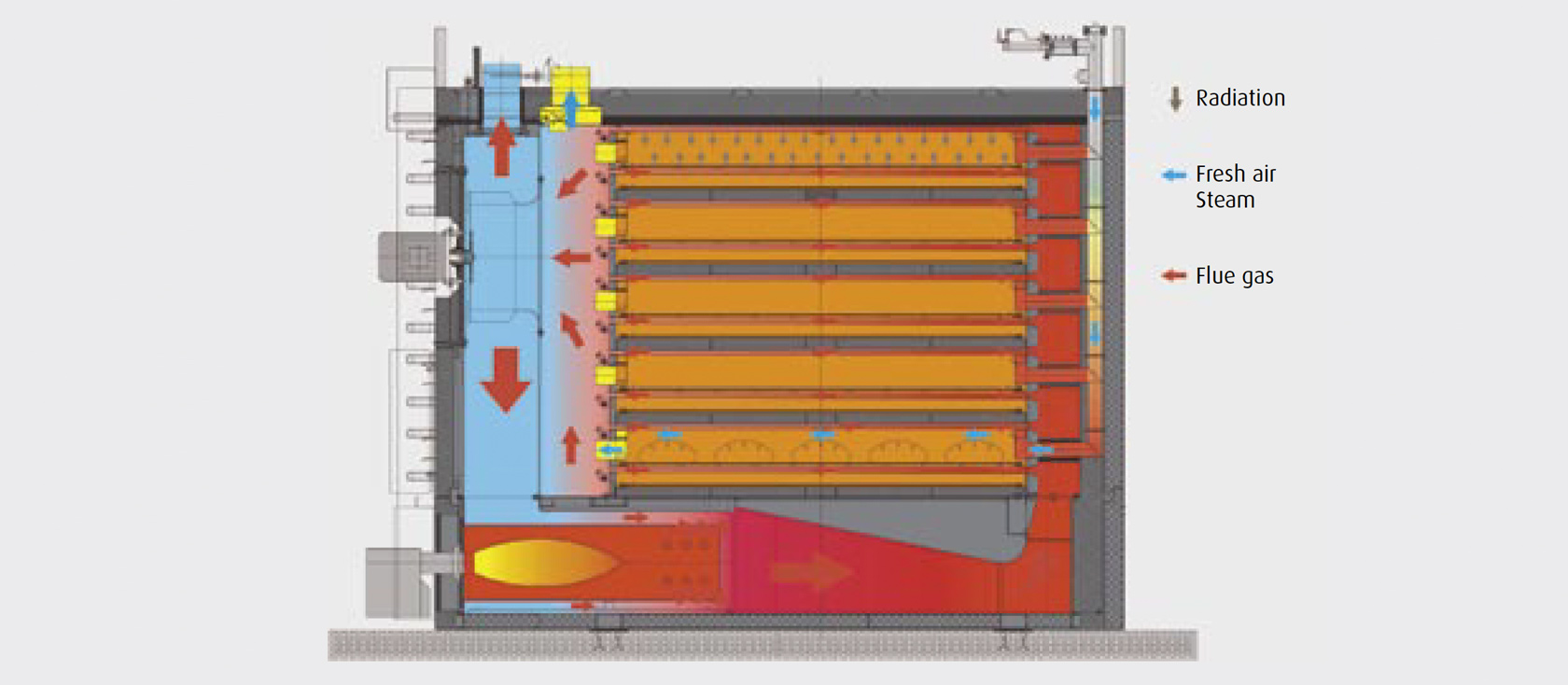

Upper and lower heating elements

Each zone has its own upper and lower heating circuit. In this way the upper and lower heating can be controlled separately. Different baking temperatures per zone can also be defined. By each oven it is possible to vary the upper and lower heating temperatures, which can differ from the other tiers.

Steam and fresh air

The MEGADOR Multi Layer Oven has a unique system for steam and fresh air intake. Steam can be injected or removed separately from each oven zone. The steam extraction unit is controlled and pressurised centrally. Direction of convection or extraction are at right angles to the running direction of the oven.

The MEGADOR Multi Layer Oven with the Thermal-oil heating system

The MEGADOR TH convinces with its constant uniformity and precise regulating, plus the use of single regulated decks or a connected series of oven zones, but even more convincing is a combination of both of these processes. In this way the MEGADOR TH can be adapted to meet your exact production requirements. And to complete the system we offer reliable loading and unloading modules and an intelligent oven climatic control system.

Thermal-oil

- Excellent constancy by means of large volume heating radiators

- Strong crusts, baking without loss of temperature when loading

- Longer lasting freshness, less loss of humidity through stronger crusts

- Especially recommended for wheat or wheat mixture products and fine baking products needing short baking cycles, i.e. tin baked loaves

The MEGADOR Multi Layer Oven with the Zyclotherm heating system

The already proven Zyklotherm heating system of the famous MATADOR deck oven is now available for multi layer ovens connected in series. The oven’s advantages are its high starting temperatures and the thereby produced high oven spring. The advantage over the Thermal-oil ovens is the versatility when temperature changes are required, which guarantees a crisp, but soft splitting crust. Loading and unloading technic and steam input or extraction are the same as in the MEGADOR TH.

Zyklotherm

- Larger baking volume by optimal steam condensation

- Soft splitting but crisper crusts through temperature flexibility

- Proofing time tolerance through excellent oven spring

- Especially recommended for darkbread mixtures with high baking temperatures

Modular construction: Innovative Modular Designed Systems

The secret of the MEGADOR Multi Layer Oven lies in its modular design. This enables the installation of a tailor-made oven solution without costly planning. The module system does not restrict your requirements, but is able to adapt to your needs due to the manifold possibilities and variations considered in its planning and design.

The MEGADOR Multi Layer Oven is a system which is adaptable to any future requirements you may have, be it expansion in your range of products, or an increase in capacity. The MEGADOR Multi Layer Oven can take on any challenge, and can be extended or adapted to your every wish. A good example is an improved automisation of the loading system, or with the Zyklotherm version it is no problem to increase the oven’s baking area. A combination of pre-baking with Zyklotherm heating and final baking with Thermal-oil is possible.

4. Oven entrance

Entrance fitted with insulated doors and integrated belt tension control on both sides.

2. Turbo ventilators with piping

Bidirectional turbo ventilators with pipes fitted at the side of the oven (Optional).

Flexible functionality: Production time and baking area are used economically

The MEGADOR Multi Layer Oven rationalises the usage of different baking and transporting processes, giving the possibility for varying the fresh products baked. This is possible when baking in tiers, or moving belt baking methods, but also when using a combination of both methods.

Continual, moving belt baking

Baking larger batches and using temperature profiles divided into zones. Loading is continuous step by step (vertical loading). This is ideal for higher production amounts and industrial production. Available for Zyklotherm and Thermal-oil.

Continual baking with a series of deck groups

Varying products are baked continuously, step by step and simultaneously in two groups of decks, even with different zone temperature profiles and step sizes. Industrial baking, automatic flow of a wide variety of baked products. Only available for Thermal-oil.

High performance, maximum benefits and modular options

With the modular EVOLUTION DONUT & BERLINER LINE, numerous products can be manufactured. True to the motto "think process", the line can be expanded into a fully automatic donut & Berliner system.

- Product quality:

- Ideal for wide range production with frequent batch changing

- In time production due to individual baking times for each layer

- Unique steam spray and fresh air systems

- Performance:

- For continual or batch production

- Separate controls of top heat and bottom heat radiators for all individual layers

- Automatic loading and unloading

- Double safety with dual drive elements (left and right), belt tensioning on both sides

- Modular:

- Choice of Zyklotherm- or Thermal-oil-Heating Systems possible

- Complete modular construction

- Hinged plate belts, grid belts or a combination of both

Baking area

24 m2 – 288 m2

Options

- on request

Industrial premium quality

through gentle baking

Natural formed or tinbaked loaves, small wheat pastries, fine tray pastries or egg-yolk sprayed specialities – with MEGADOR you always achieve first class results.

Pretzel

Croissant

Kaiser rolls

Square rolls

Finn breads

Mixed breads

Bauernbrot